Non-molybdenum sulfide copper-molybdenum separation

Classification | Craft or pharmacy | ||

Inhibitor only | Molybdenum floating copper | Dextrin inhibits molybdenum, xanthate captures copper minerals | |

Copper-free molybdenum | Cyanide | NaCN, KCN, Na 4 Fe(CN) 4 , Na 3 Fe(CN) 4 | |

Sulfide | Na 2 S, NaHS, (NH 4 ) 2 S | ||

Knox | P-Nokes (LR-744), As-Nokes (Anamol-D) | ||

Organic inhibitor | HSCH 2 COONa, HSCH 2 CHOH, etc. | ||

Oxidant + inhibitor | NaOC+Na 4 Fe(CN) 6 ;H 2 O 2 +Na 4 Fe(CN) 6 | ||

Nitrogen-filled + inhibitor | N 2 +Na 2 S(NaHS); N 2 +Nokes | ||

Heat treatment + inhibitor | Roasting method | Filtration-roasting-sorting | |

Steaming | Concentration-steaming-sorting | ||

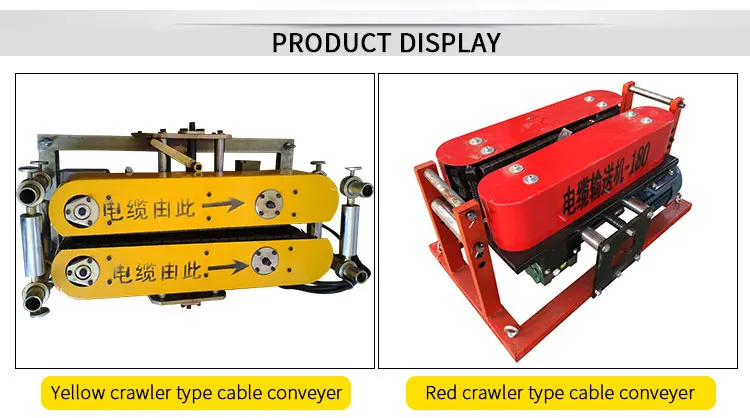

Cable conveyer details:

Usages

DSJ series product is an electric machine for laying power cables (or communication cables).

Packing

Cable conveyer be packed in cartons or pallet.

Applications

Cable conveyer applied in Long distance cable laying.Small volume, light weight, easy to operate.

Features:

1. The two vertical shafts drive the transmission force and gravity respectively in two directions of the cable to protect the insulation of the cable.

2. The transmission force is transmitted through the compound caterpillar, and cater pillar adopts high strength wear-resisting rubber, which make the power force uniform and durable.

3. The machine is equipped with adjustable roller, which is very convenient.

4. The upper part of the machine can be fitted with a hinge wheel, which can be used for small power traction.

5. The machine has low mechanical noise, small temperature rise and easy maintenance.

6. Support products can be provided by user, like –DSJ series electrical control system (total control box, control box) and winding wheel etc.

Data sheet of Cable conveyer:

| Model | Advance speed | Range of use | Conveying force | Dead weight |

| DSJ(G)-150 | 10.4 | Φ60-150 | 5.5 | 120KG |

| DSJ(L)-150 | 7 | Φ60-150 | 3.8 | 135KG |

| DSJ(L)-180 | 7 | Φ60-180 | 5 | 160KG |

Cable Conveyer,High Strength Cable Conveyer,Electric Cable Conveyer,Cable Conveying Machine

Hebei Long Zhuo Trade Co., Ltd. , https://www.hblongzhuo.com